Secure by inserting a fastener through the hole at the base.

High stiffness compression springs.

High load fastener mount compression springs.

This has as much to do with your tension spring design as your spring s rate does because it will also affect your spring s working loads.

Helical compression is the most common metal spring configuration.

They have large wire diameters from 1 4 inch to 1 inch in thickness and are required when the spring needs to support a large amount of load in a mechanism.

For the heaviest loads these springs have more than double the load capacity of high load fastener mount compression springs.

It is also mostly based on proportion though.

Designed to fit in small holes from 1 8 to 2 and preset too solid height.

Coil compression springs with light spring rates based on its physical dimensions.

A light compression spring is a spring that might have a small or average wire diameter paired with an outer diameter that corresponds to a spring index no smaller than a 7 to 1 spring index.

Compression springs are often pre set at the factory.

After years of extensive engineering design and materials research lee spring s technical team has developed this unique compression spring offering.

Spring stiffness is based on spring rate.

A ten pound rate may not seem like much on a large spring but on a small spring it might be just enough.

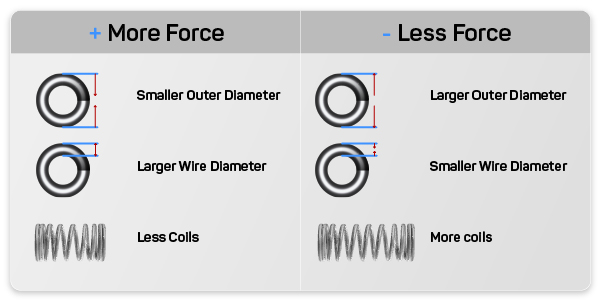

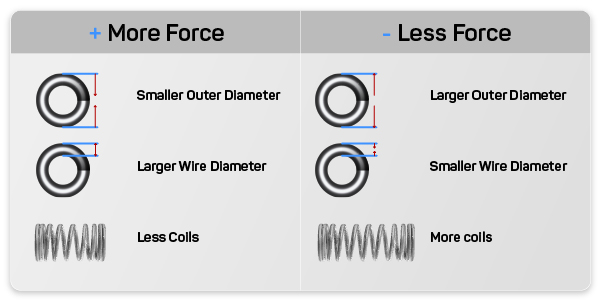

If you lower the amount of coils you ll increase the spring stiffness which is the spring s rate.

These springs handle higher loads than standard fastener mount compression springs.

Initial tension is the tension gathered in between your spring s coils before it is extended.

A compression spring s set is the final length the spring takes after deflecting under a load and not returning to its original height.

Leep is lee spring s response to increased requests for springs that combine the strength of metal with the special attributes of high performance engineered thermoplastics.

High pressure compression springs are a series of slender low index compression springs with relatively high pressure ratings compared to standard compression springs.

Learn more about compression springs.

The high pressure series is made of 17 7 stainless steel with participation hardening heat.

Heavy duty springs are compression extension or torsion springs with a great amount of force.

Compression springs are open coil helical springs wound or constructed to oppose compression along the axis of wind.